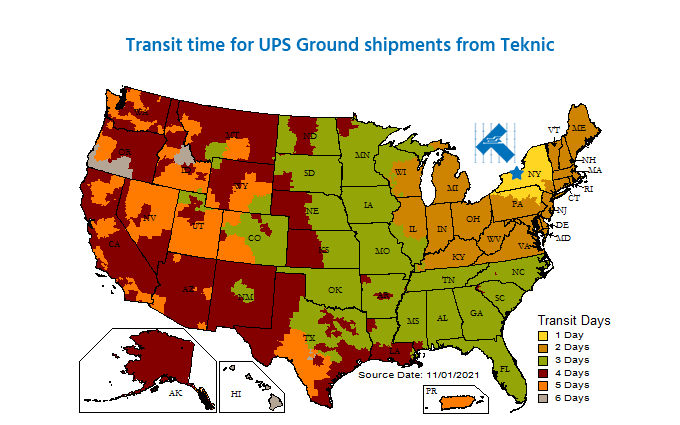

Yes, all of the items on our eCommerce store (ClearPath, ClearPath accessories, and power supplies) can be shipped internationally. Currently, we support shipping to:

Albania, Argentina, Armenia, Australia, Austria, Bahrain, Bangladesh, Belarus, Belgium, Bolivia, Bosnia and Herzegovina, Brazil, Bulgaria, Canada, Chile, China, Colombia, Costa Rica, Croatia, Cyprus, Czech Republic, Denmark, Dominican Republic, Egypt, El Salvador, Estonia, Fiji, Finland, France, Germany, Greece, Guatemala, Honduras, Hong Kong, Hungary, Iceland, India, Indonesia, Ireland, Israel, Italy, Japan, Jordan, Kenya, Kuwait, Latvia, Lebanon, Libya, Lithuania, Luxembourg, Macedonia, Malaysia, Malta, Mexico, Moldova, Morocco, Namibia, Netherlands, New Caledonia, New Zealand, Norway, Oman, Pakistan, Paraguay, Peru, Philippines, Poland, Portugal, Puerto Rico, Qatar, Romania, Saudi Arabia, Serbia, Singapore, Slovakia, Slovenia, South Africa, South Korea, Spain, Sri Lanka, Sweden, Switzerland, Taiwan, Thailand, United Arab Emirates, United Kingdom, United States, Uruguay, and Vietnam.

Your shipping price will depend on the order size, type of products, destination, and shipping speed. This will be shown on the “Shipping Method” page during checkout.

Please note: Some countries charge additional customs fees and carrier charges. Teknic cannot anticipate these costs. Before placing your order, please contact your local customs office to inquire about any fees that you may expect. Teknic will not reimburse you for any additional fees incurred.

For more information, please see the FAQ section "Are there any other charges, such as duties or taxes?"

Additional charges are not included in Teknic's shipping charges.

Teknic's international shipping charges include express air transportation, brokerage fees, and clearance entry fees, but your destination country may charge you import duties (tariffs) and/or taxes and other fees for the products you import from Teknic. These charges are not included and must be paid by you upon receipt of your shipment.

Unfortunately, we cannot calculate what your additional charges may be, because customs and taxation policies vary widely from country to country. As a general guideline, the European Union duty rate for ClearPath motors is 2.7%; the global average import duty rate is about 4%; rates of 8-12% are not uncommon; and a few countries are higher. For exact details, please contact your destination’s customs office or visit their official website.

The tariff codes for the products available on our website are as follows:

| Product Type | Harmonized System (HS) Tariff Code |

|---|

| DC Input (Fractional hp) ClearPath Servo Motors | 8501.31.4000 |

| AC Input (Integral hp) ClearPath Servo Motors | 8501.52.3000 |

| RES-225 Regenerated Energy Shunt | 8536.30.0000 |

| BLOWER-1P230V Blower Kit | 8503.00.6060 |

| FOOT-56-14X Mounting Foot | 8503.00.6060 |

| IPC-3 and IPC-5 Power Supplies | 8504.40.9530 |

| ASU-FR510 Analog Send Unit | 8534.00.0040 |

| Cables | 8544.42.0000 |

| ClearCore, ClearLink, and CCIO-8 | 8534.00.0040 |

| Terminal Block Plugs | 8536.90.4000 |

| 24 VDC Power Supply | 8504.40.9520 |

| Atmel-ICE Debugger | 8534.00.0040 |

| DIN Rail Mounting Kit | 8302.42.3065 |

| Power Hub and SC Hub | 8534.00.0040 |

| NEMA 23/34 Hudson Servo Motors | 8501.31.3000 |

| NEMA 23/34 Motor Brakes | 8505.20 |

| M12 Network Connector Adapter | 8517.62.0000 |

| M12 Coupler | 8544.42.0000 |

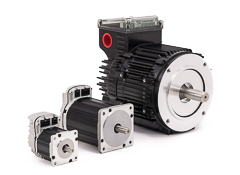

ClearPath integrates all servo components into one compact package:

ClearPath integrates all servo components into one compact package: