| Feature | Description | Basic Version

(Standard) | Advanced Version

(Optional) | Jerk-limited

positional moves | Make relative or absolute moves with automatic jerk limiting and jerk-derivative limiting for ultra-smooth motion. | | |

| Velocity moves | Ramp up or down to user-selected velocities and rotate continuously. Programmable settings control acceleration, jerk (rate of change of acceleration), and jerk derivative for ultra-smooth changes in speed. | | |

| Flexible homing routines | Home to a limit switch or hardstop (with gentle, torque-limited hardstop detection). User-defined homing routine can be pre-configured and invoked with one line of code. | | |

| Read measured position, velocity, torque, and much more | Full access to real-time status of all motion parameters (more than 30 different status indicators) | | |

| Safety shutdowns | Constant, automatic monitoring of a variety of motor operating conditions, and shutdowns as necessary to prevent motor and/or system damage. | | |

| Soft limits | Set software end-of-motion limits to prevent accidental crashes (can be used simultaneously with physical limit switches). | | |

| Global torque limiting | Programmable limit on the maximum amount of torque. | | |

Automatic brake

coil control | Automatically engage a third-party fail-safe brake when an axis shuts down or is disabled. | | |

| Group shutdowns | Automatically stop all motion axes simultaneously when any axis has a problem. Also, a global stop input allows non-programmatic simultaneous stopping of all axes using a digital input, button, or switch. | | |

Up to 16 axes per

com port | Using low-cost SC Hub boards ($49), create up to 4 "mini-networks" of up to 4 axes each, which can be daisy-chained (distributed or plugged directly into each other without cables) to allow maximum flexibility and minimal wiring. | | |

| Robust communication | Innovative hardware and communication design allows high command throughput (over 1,000 commands per second) without using noise-sensitive high-speed circuitry or non-deterministic "crash and retry" protocols. All inputs are optically isolated for even more noise immunity. | | |

| Automatic network configuration | No need for setting DIP switches or programming network addresses. Just power up the system and each axis is automatically addressed based on its position in the network. | | |

| g-Stop™ anti-vibration move profiles | Motion profile sculpting based on patented anti-vibration technology. Allows the fastest possible moves without exciting mechanical resonances in the machine. Easy to configure, and robust operation even as mechanics wear over time. See video demonstration. | | |

| Triggered moves | One or more axes can be configured to start simultaneously upon command or electronic signal for the most precise synchronization requirements. | | |

| Head-tail moves | Create two- or three-part move profiles where the beginning and/or the end of the moves are at a different maximum velocity than the middle part of the moves. This is useful for making fast moves with one or two slower segments (e.g., moving past a camera slowly and then moving to a target quickly, or slowly clamping something at the end of a fast move). | | |

| Asymmetric moves | Create move profiles with different acceleration and deceleration limits. Often, because of friction (or gravity), an axis can decelerate faster than it can accelerate, and this feature allows faster moves in these cases. | | |

| Trigger events at user-defined positions | Get a notification when an axis reaches a certain position (either after the start or before the end of the move) to allow synchronization with other events or processes. | | |

| Positive/Negative torque limiting | Independently limit positive torque and negative torque (typically used in clamping applications). | | |

| Conditional torque limiting | Automatically limit torque (positive and/or negative torque) when an axis is in a certain positional zone, or based on an electrical signal, or when a move completes. | | |

| Attention generation | Automatically generate interrupts based on user-defined events so that you don't have to constantly poll for them. This creates a more responsive and synchronized system. | | |

| Position capture | Precisely capture axis position on-the-fly based on an electronic input. | | |

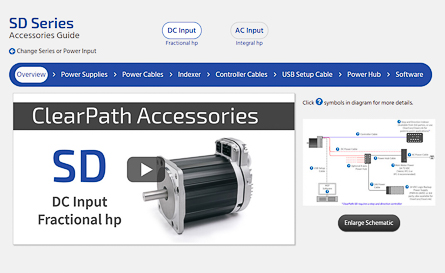

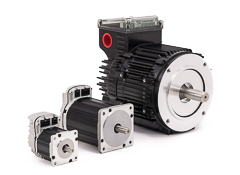

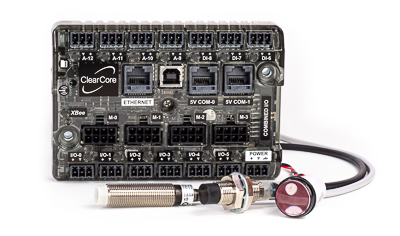

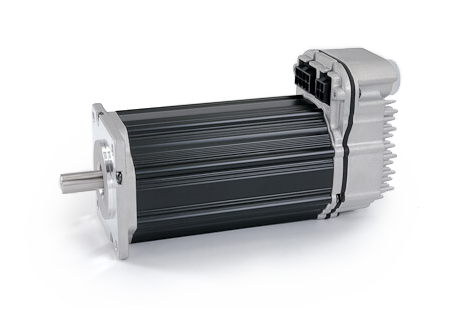

ClearPath All-in-One Servo MotorsClearPath integrates all servo components into one

ClearPath All-in-One Servo MotorsClearPath integrates all servo components into one