| 3 ClearPath-SDSK servo systems have 2-3 times the power of similar sized steppers and cost less. | 1 High inductance and high pole count causes torque to drop off rapidly with speed, leading to lower power output. | 5 ClearPath-SDHP servo systems have 8-15 times the power of similar sized steppers, and more power than many similar sized servos due to the vector sinewave torque control and high energy rare-earth magnetics. | 5 Most brushless servo systems have constant torque out to relatively high speed, which means lots of power. |

- ABOUT

- PRODUCTS

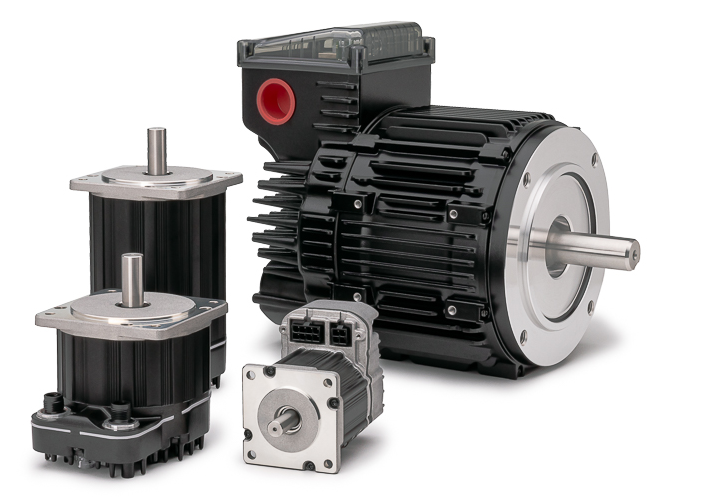

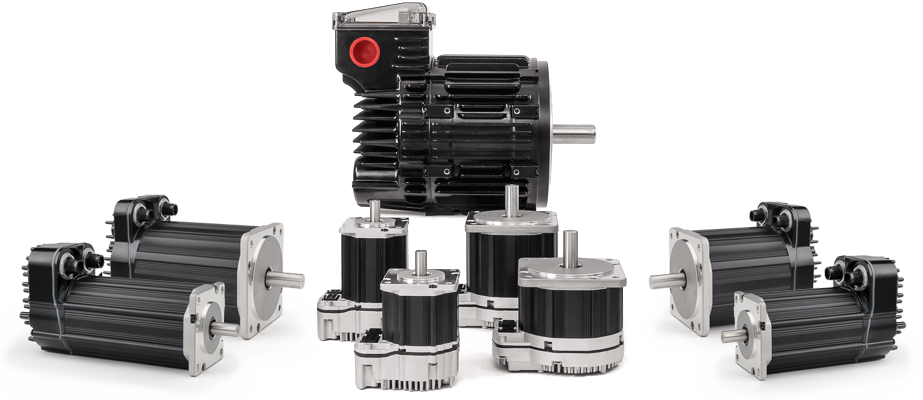

- ClearPath All-In-One Servo MotorsClearPath Overview Why ClearPath? Compare... Choose Series Motor Selection Guide Accessories Guide Motor Specs Index: All Motors/Accessories EtherNet/IP ControlClearCore I/O & Motion Controller ClearLink EtherNet/IP Motion & I/O Controller IPC DC Power Supplies Hudson BLDC Servo Motors Meridian Integrated Controllers Eclipse Digital Servo Drives Motor Brakes Legacy ProductsTeknic Motion Control ProductsTeknic offers a variety of industrial machine automation products, including BLDC servo motors, servo drives, motion & I/O controllers, and power supplies. Some of our products (Meridian, Eclipse) are available only to OEMs with a minimum purchase requirement. We sell our fully-integrated ClearPath motors, ClearPath accessories, Hudson BLDC servos, ClearCore controllers, ClearLink EtherNet/IP controllers, and DC power supplies on our website. If you have questions about our products, please contact us for more information.

ClearPath All-in-One Servo MotorsClearPath integrates all servo components into one

ClearPath All-in-One Servo MotorsClearPath integrates all servo components into one

compact package:- Motion controller

- Brushless, permanent magnet motor

- High-resolution encoder

- Digital servo drive electronics

- 3-year warranty

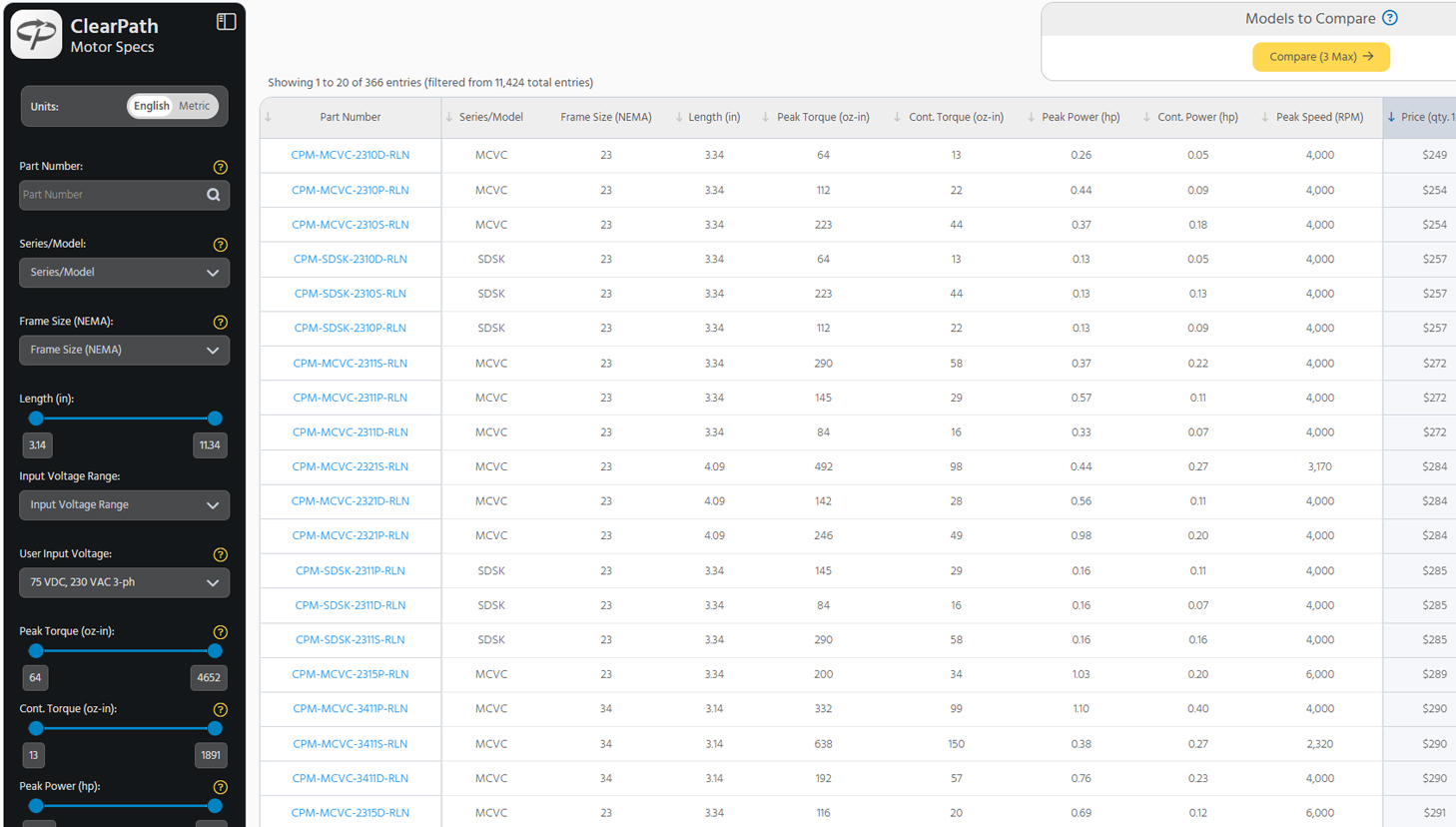

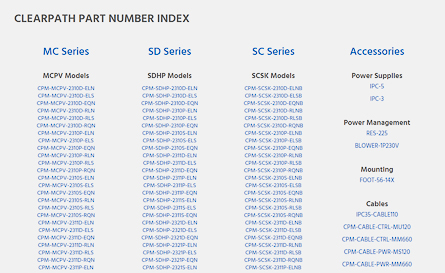

ClearPath Motor SpecsFor engineers that already know their ClearPath series and exact requirements:- See specs and pricing for 1000+ part numbers

- Filter by torque, speed, power, voltage, frame size, length, and more

- Overlay torque vs. speed curves and compare specs and pricing

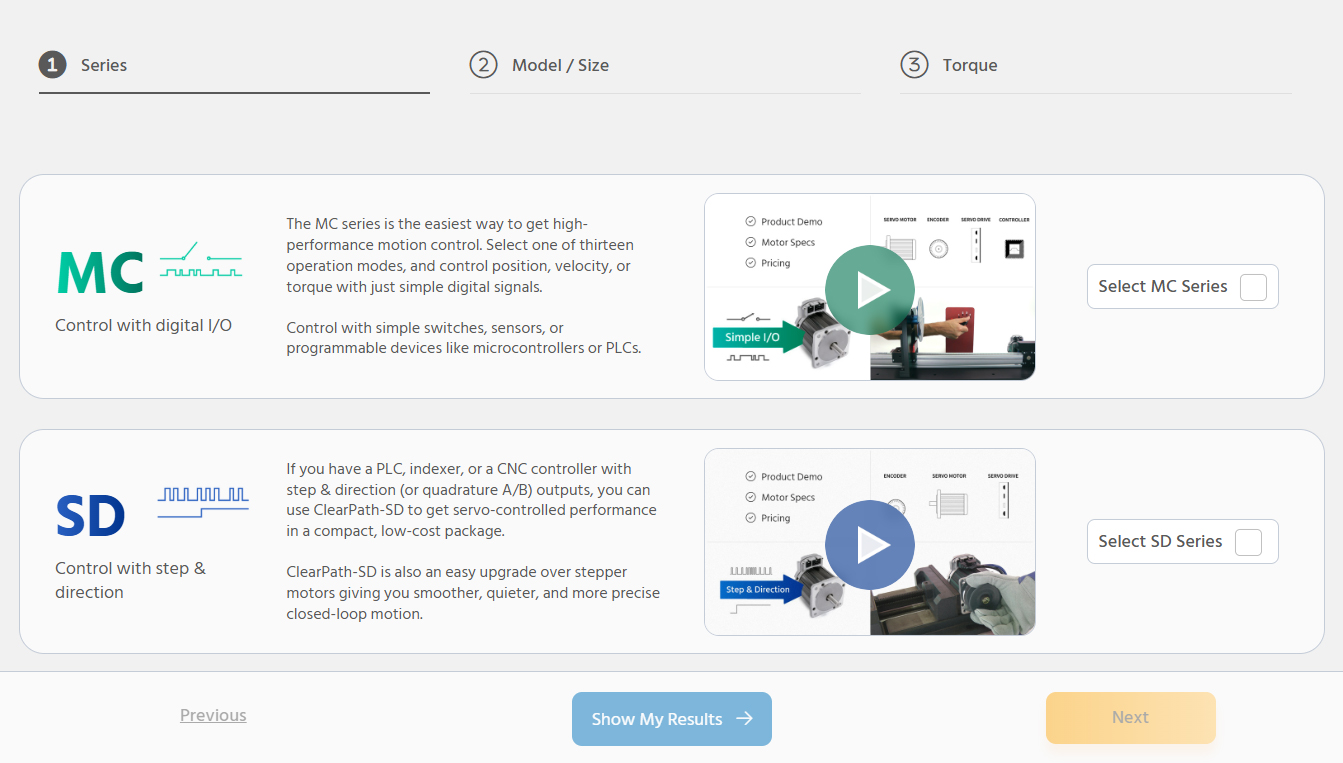

ClearPath Motor Selection GuideIf you need help selecting the right ClearPath motor, use this guide to narrow your options in 3 easy steps.- Choose your series, model, and power range

- Get a list of relevant specs and pricing

- Compare ClearPath models side-by-side

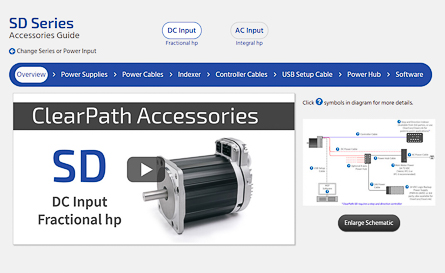

ClearPath Accessories GuideFor help with selecting accessories for your specific ClearPath system, use this walkthrough.- Step-by-step guide to select recommended and optional accessories

- Comprehensive overview video for each accessory

- Use the interactive accessories schematics to easily purchase the parts you need

ClearPath Index: All Motors & AccessoriesIf you already know your part number(s), use the index to quickly find:- Pricing and ordering of ClearPath motors or accessories

- Specifications (including torque vs. speed curves)

- Drawings, manuals, or setup software

Control ClearPath servos with your EtherNet/IP PLC

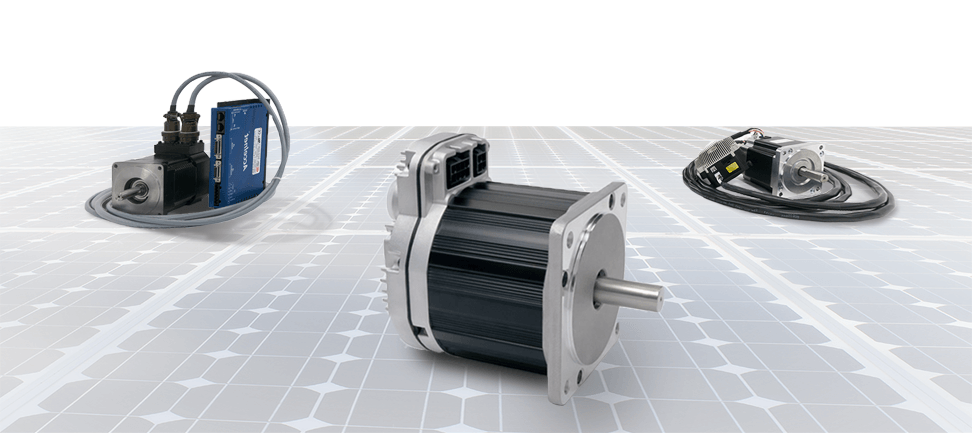

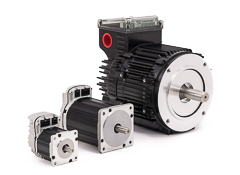

using a ClearLink controllerHudson BLDC Servo MotorsTeknic's Hudson servo motors are designed to excel in the most demanding OEM applications, and provide benefits including:- Reduce motor footprint and maximize power output with optimized magnet shape, motor skew, and rotor geometry.

- Improve machine reliability with a brushless servo motor designed with oversized bearings, class H windings, and 3-year warranty

- Increase machine performance with Hudson's high torque density and fast electrical time constant

- Designed, built, and tested in the USA

Meridian Integrated ControllersMeridian is an integrated motion controller and digital servo drive that is capable of controlling servos, linear motors, and steppers. Benefits include:- Reduce machine vibration and increase throughput with g-Stop™ anti-resonance

- Use the Accelerated Prototyping System™ to diagnose machine performance, reduce development time, and get your machine to market faster

- Improve stepper motor smoothness and increase power output with Meridian's vector sinewave commutation

- Meridian's "sFoundation" is a source code library that provides the majority of the motion functions you'll need to get your system up and running quickly

- 3-year warranty

Eclipse Digital Servo DrivesEclipse is a state-of-the-art digital brushless servo drive capable of controlling brushed and brushless servo motors. Benefits include:- Reduce move and settling time, audible noise, mechanical wear, and more with the RAS Motion Smoothing Algorithm

- Eliminate overshoot and improve machine performance with Teknic's proprietary servo algorithms

- Reduce development time with Quickset's digital oscilloscope and move generator

- 3-year warranty

Motor BrakesSpring applied power-off (or fail-safe) brakes are used in applications that require the axis to stay in position, even if the machine loses power or is turned off (this is common for vertical applications or when additional safety measures are required).- Front mount compatible with any NEMA 23 or NEMA 34 motor frames

- 24VDC input for easy actuation

- NEMA 23 pricing starting at $219 and NEMA 34 at $296

- Buy Online; 90-day satisfaction guarantee; 3-year warranty

IPC DC Power SuppliesThe Amazon™ Intelligent Power Center (IPC) is designed and built specifically for motion control applications.- High output capacitance and built-in regen control system prevents over-voltage shutdowns and the need for external regeneration control and load resistor

- High peak power drastically reduces power supply droop during motor acceleration

- Buy online, starting at $199

- Built in the USA; 3-year warranty

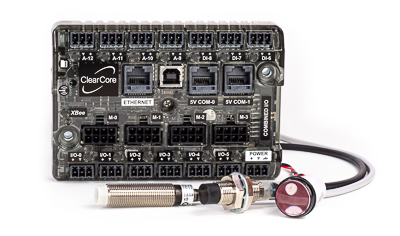

ClearCore I/O and Motion ControllersClearCore is a controller platform for industrial I/O and motion control.- Control 4 steppers or digital servos like ClearPath

- Analog/digital inputs and outputs; 24V industrial quality

- Rich C++ library with dozens of example programs

- Ethernet and serial communication

- Buy online; 90-day satisfaction guarantee; 3-year warranty

ClearLink EtherNet/IP Motion and I/O ControllerClearLink is an industrial I/O and motion controller, compatible with any EtherNet/IP scanner.- Control 4 steppers or digital servos like ClearPath

- Configurable analog/digital inputs and outputs; 24V industrial quality

- Rich EDS file support reduces development time

- Add up to an additional 64 digital I/O at $6 per point

- Buy online; 90-day satisfaction guarantee; 3-year warranty

Teknic Legacy ProductsTeknic continues to advance the state-of-the-art in servo motion control. As a result, new products are engineered to provide greater performance, reliability, and value. Products that are eventually displaced by the introduction of new technology are not simply discontinued—the components continue to be manufactured and supported for as long as parts are reasonably available.When products are forced into end of life, Teknic's factory engineers work with customers who desire to extend the life of their legacy machines with newer servo components. Some of Teknic's legacy products were available for nearly 30 years before they moved to end of life status.

- SUPPORT

- DOWNLOADS

- CONTACT

-

Cart 0

ClearPath-

ClearPath-